In the world of industrial valves, choosing the right partner isn’t just about evaluating a price: it means choosing quality, safety, support, and continuity. Here are 5 key elements to consider when selecting a reliable manufacturer – and why MTM Valves can be the right choice.

1. Certifications and Compliance

Always verify that the manufacturer possesses the main certifications required by your industry: PED, ATEX, ISO 9001, ISO 14001, API 6D, etc. MTM Valves is certified by internationally recognized third-party entities and provides valves suitable for classified and high-risk environments as well.

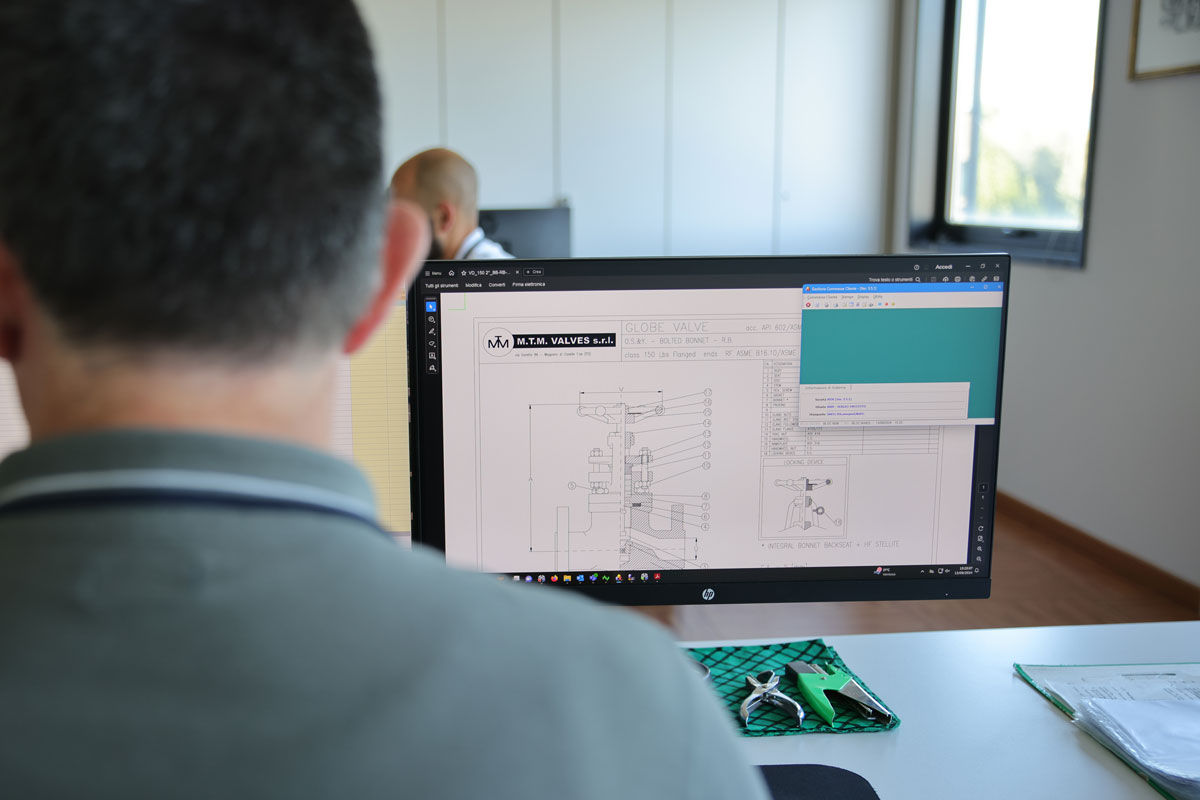

2. Controlled Production Process

From design to delivery, every phase must be traceable and verifiable. MTM Valves has adopted a structured method that integrates advanced CAD design, rigorous testing, and an automated warehouse that ensures rapid deliveries and always available components.

3. Customization Capability

Every plant has unique needs. A good manufacturer must be able to design and build custom valves, even non-standard ones. MTM specializes in customized valves, which can be produced in small batches and in special materials such as titanium, zirconium, and superalloys.

4. Quality of Materials and Technologies Used

The choice of materials, the quality of workmanship, and the tests performed are crucial. MTM works only with certified materials and adopts advanced technologies to ensure high performance even in extreme operating conditions.

5. Support and Long-Term Reliability

Beyond the product, service also matters. The MTM team is always available for technical assistance, design consultations, and after-sales support. The relationship with the customer is seen as a shared journey, not as a one-time transaction.

Choosing the right manufacturer means investing in safety, continuity, and value. MTM Valves is ready to support you with experience, expertise, and a range of solutions built to last.