MTM Valves stands out for a team of professionals who combine experience and passion, transforming an idea into a reality known internationally. Founded in 1996 from the expertise accumulated over years in the industry, MTM Valves has embraced the challenges of an ever-evolving market, finding a niche in creating high-quality solutions with speed & precision to meet specific needs, avoiding plant downtime, and ensuring maximum operational efficiency for clients.

The Company

Competent and Competitive

Experts in the production of forged valves for the petrochemical, chemical, and energy sectors.

Products

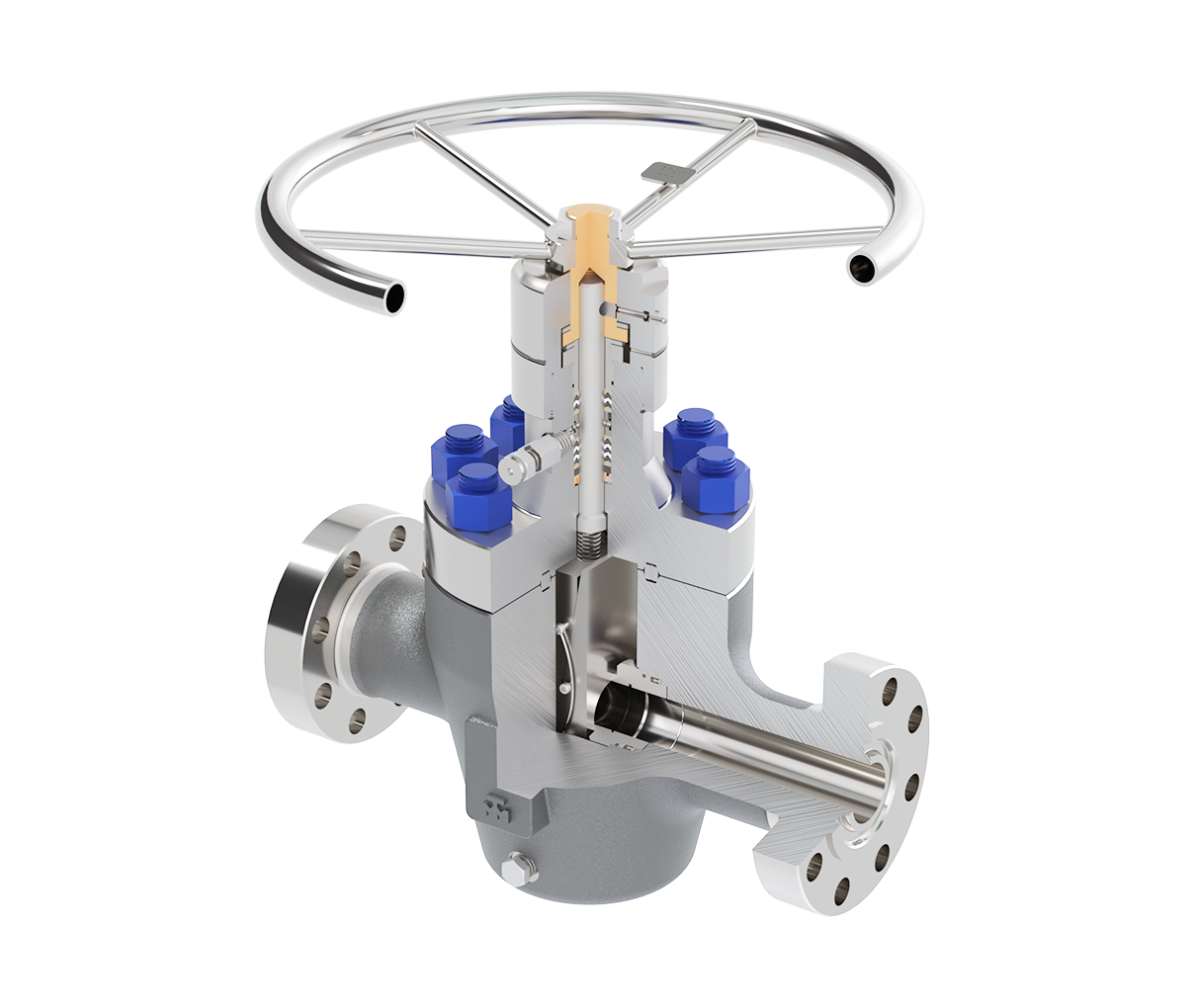

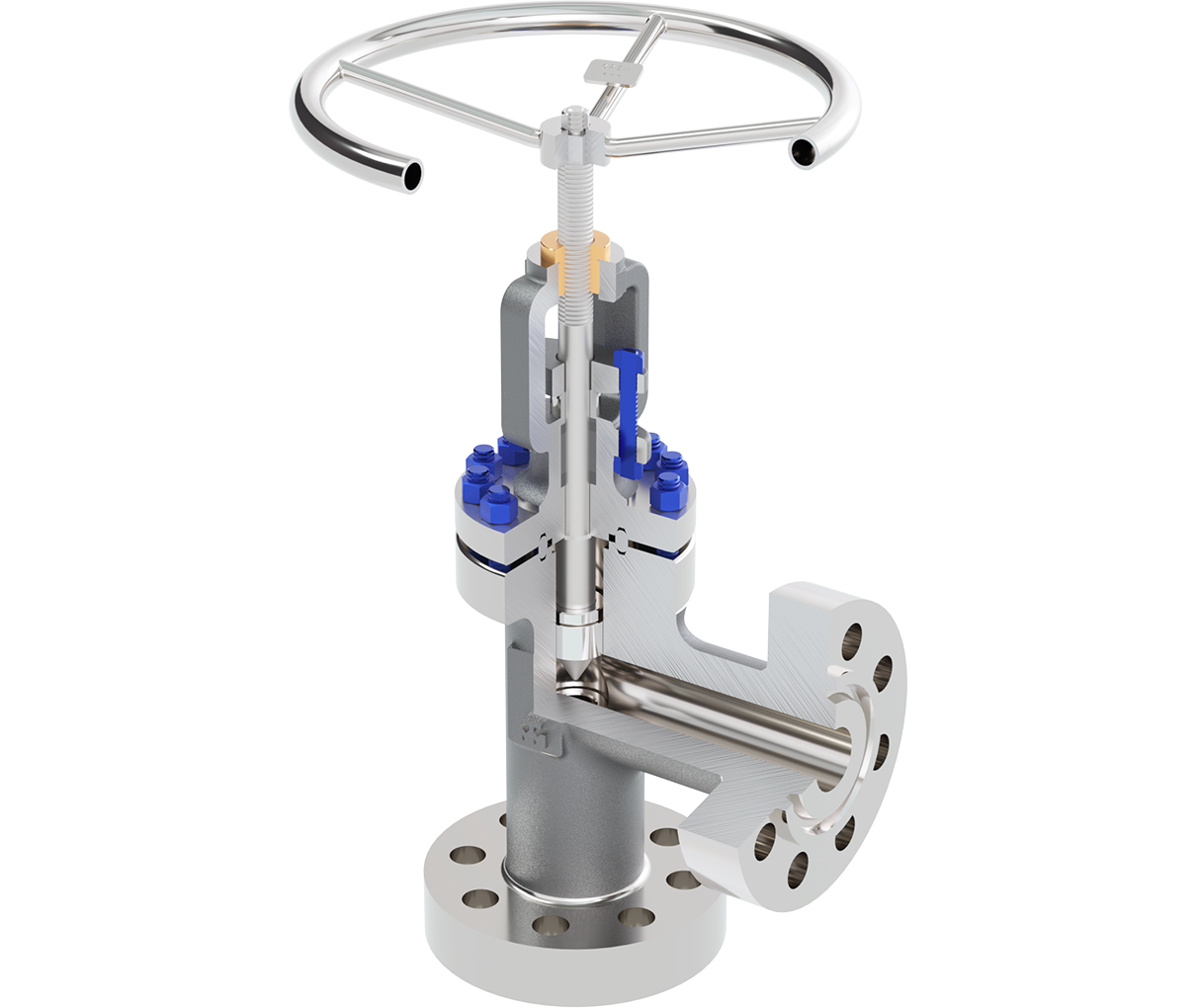

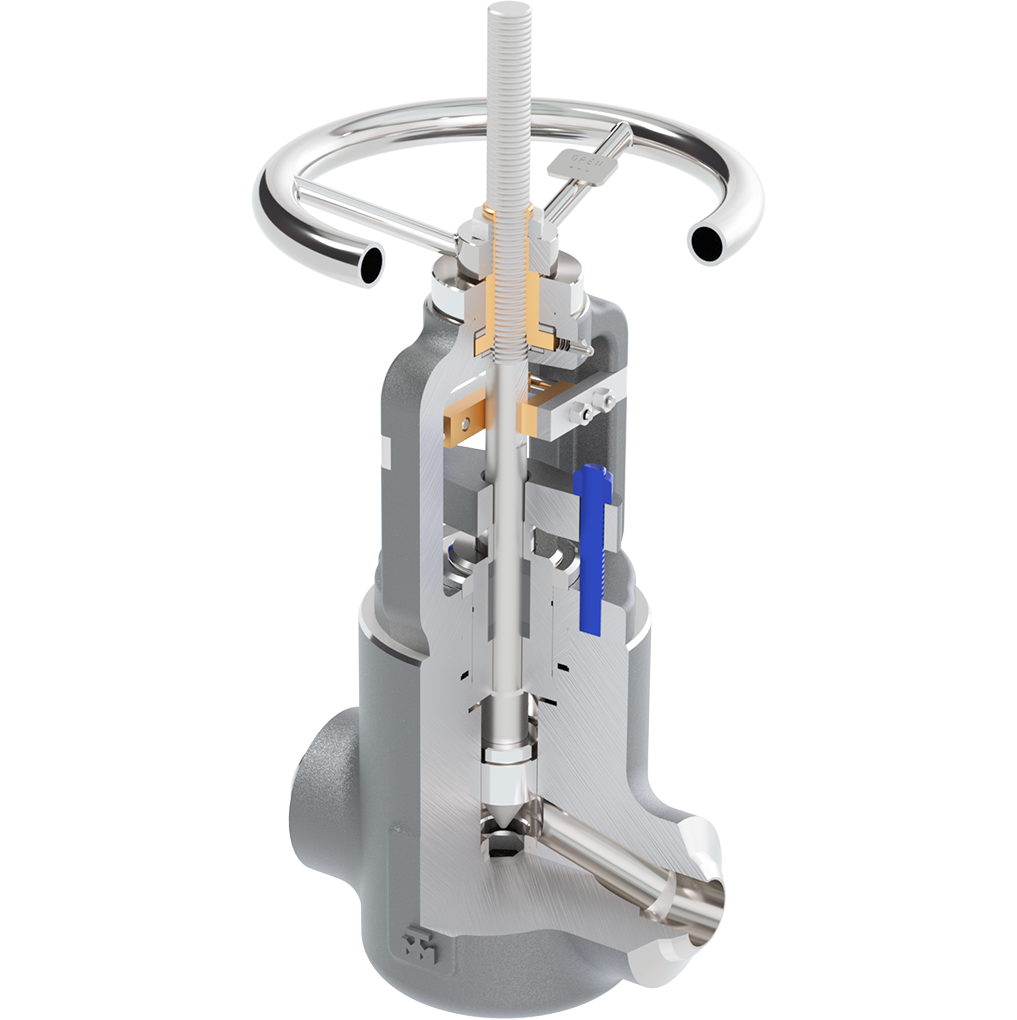

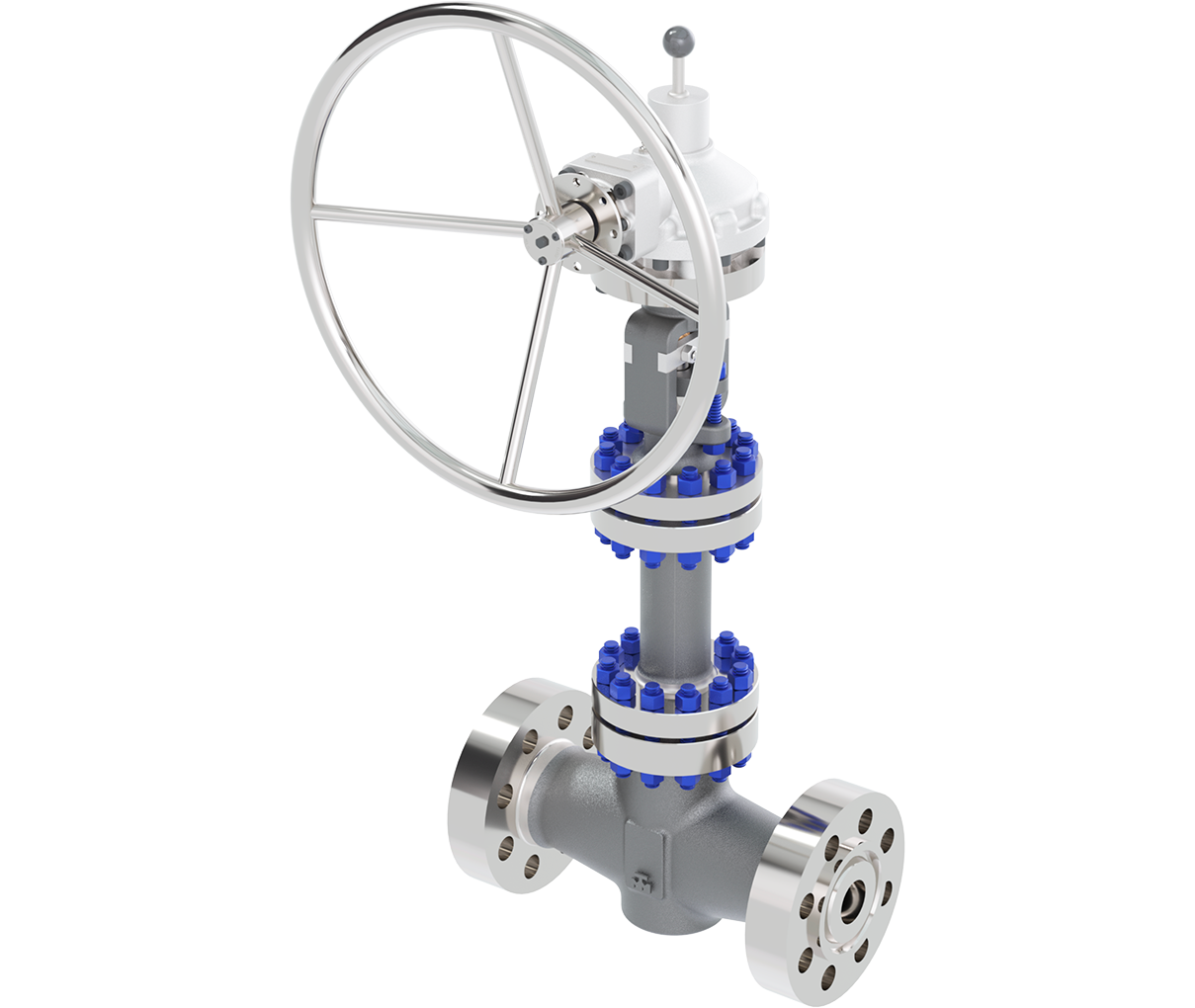

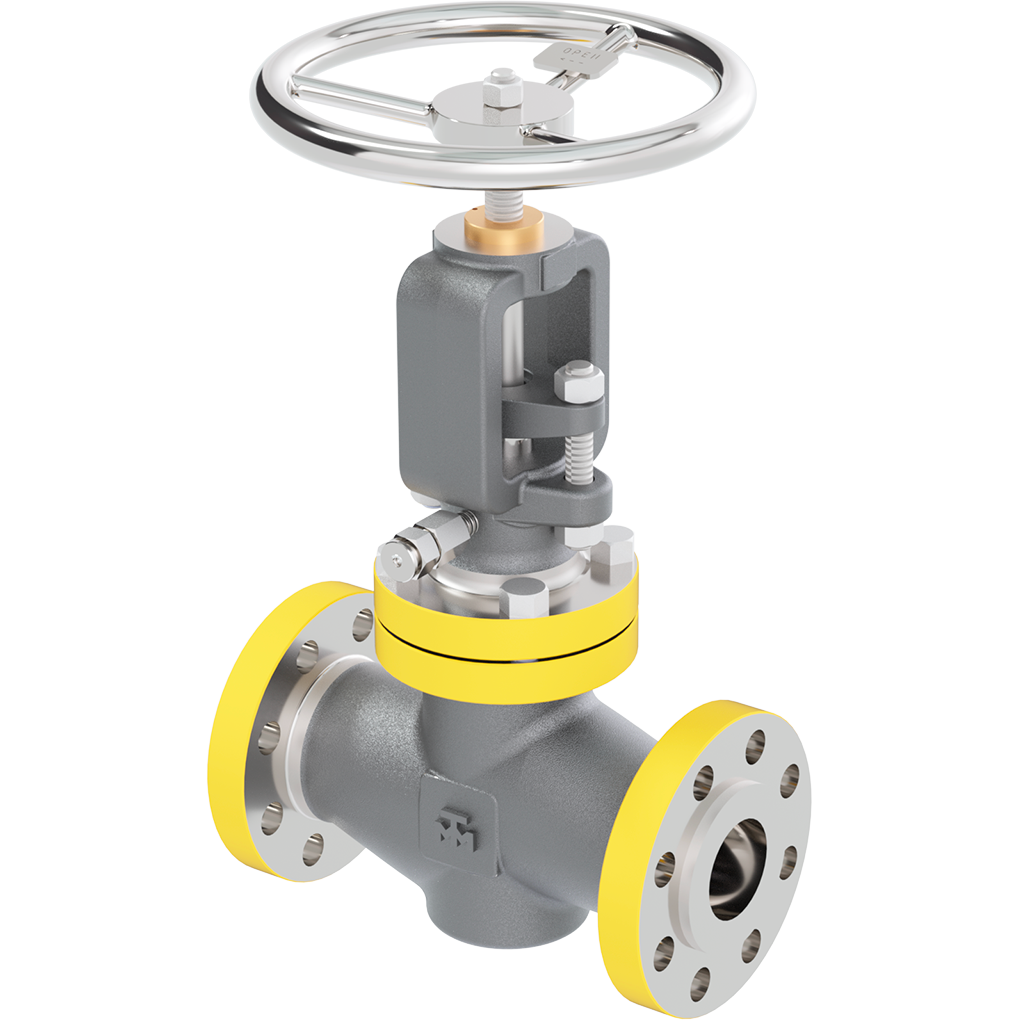

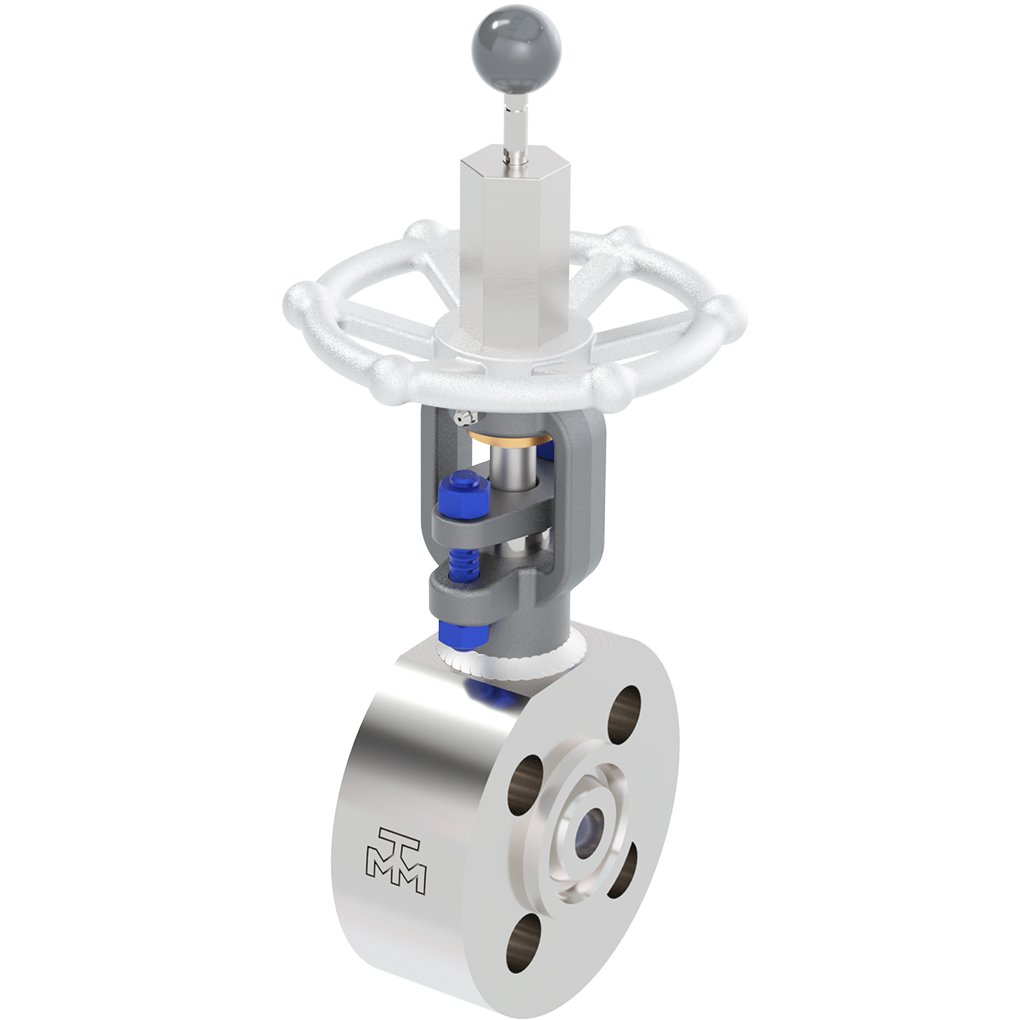

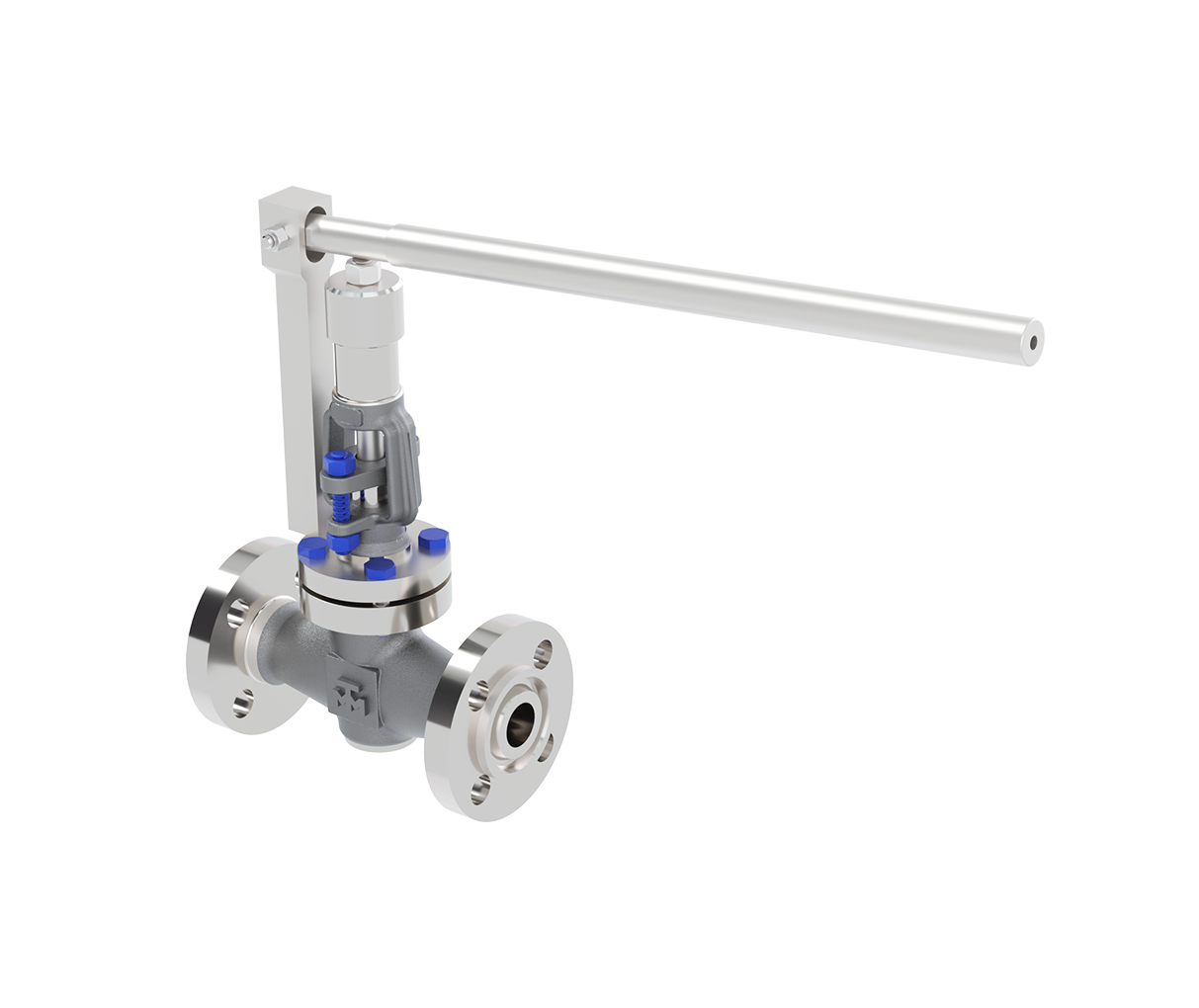

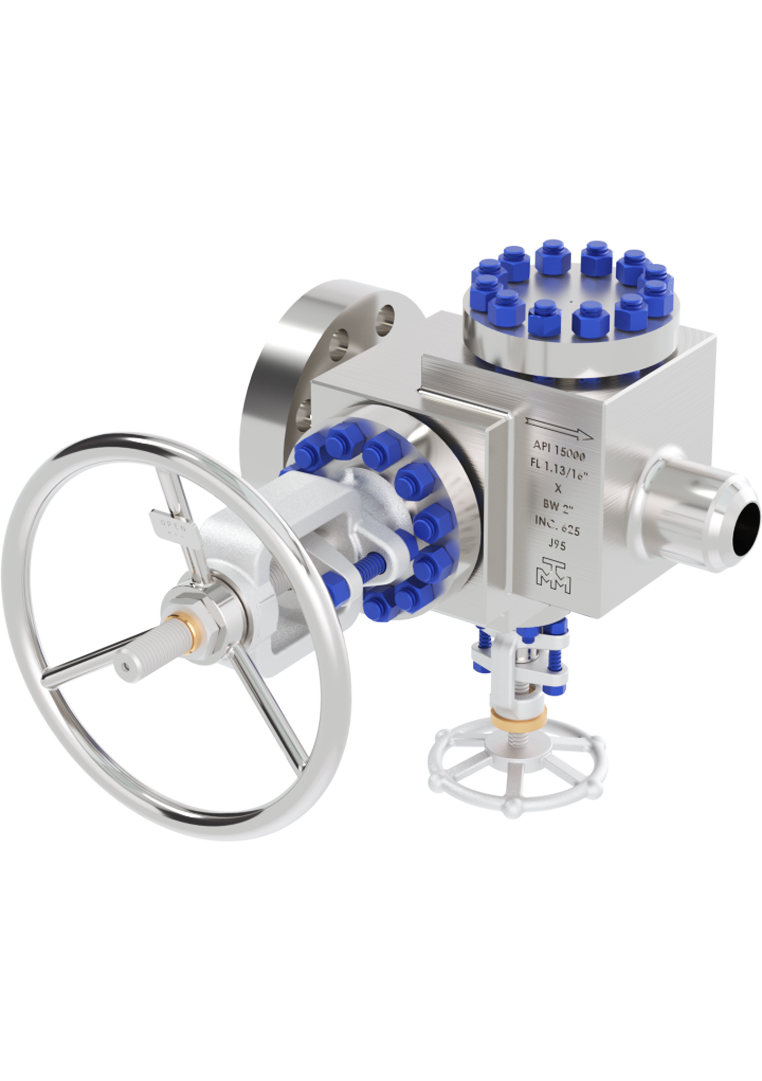

High-quality forged industrial valves for critical applications

We offer a complete range of valves for critical applications, made with high-quality materials for every need. Available in various sizes and pressure classes, our valves ensure operational efficiency and maximum safety.

We also work with innovative materials, offering cutting-edge solutions for small productions.

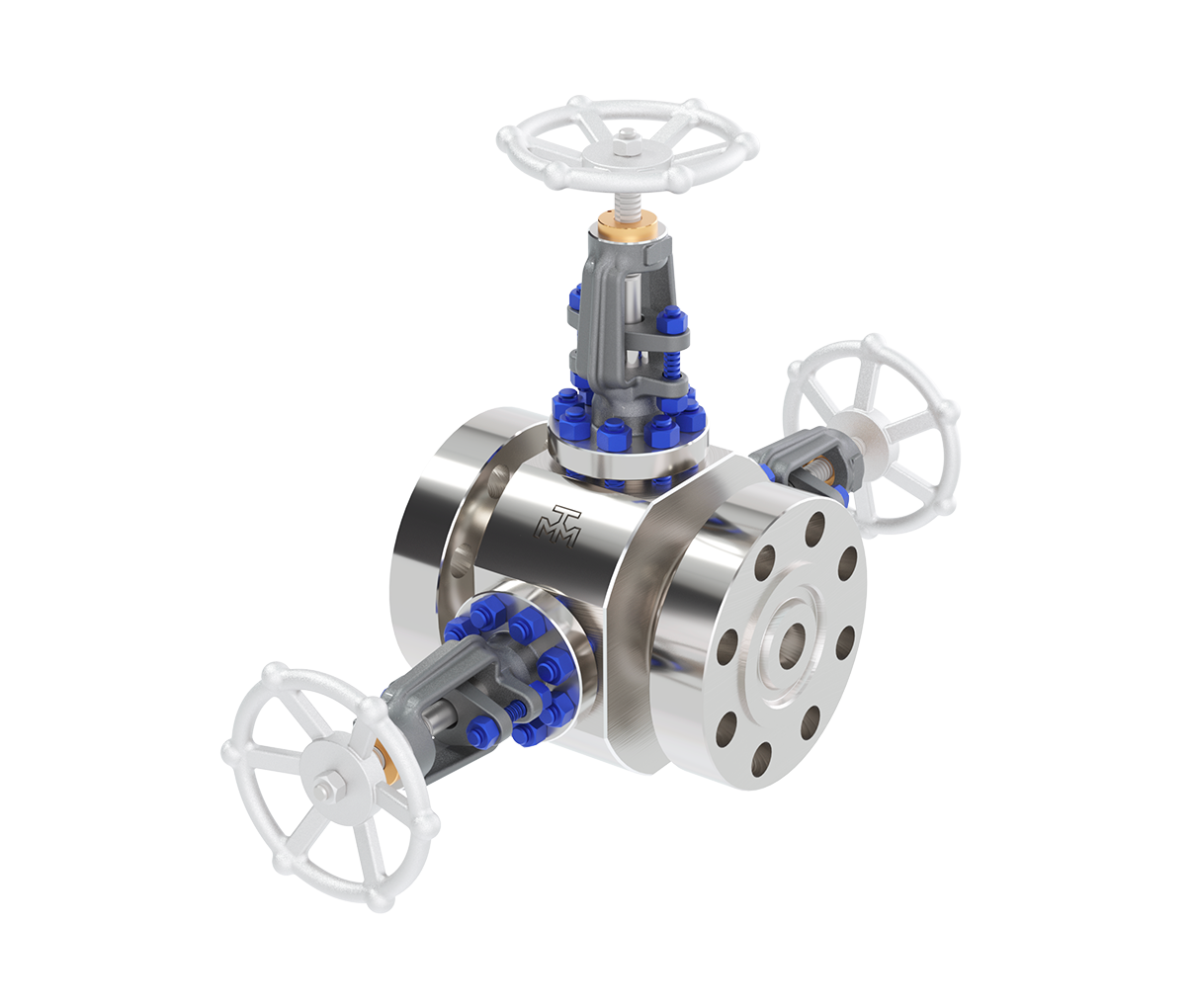

Special Products

Beyond standards: customized valves.

We comply with regulations, meeting the most complex requests.

International standards define technical characteristics, but not all needs fit these standard parameters. This is where MTM Valves comes into play.

Thanks to our flexibility, we can design and produce valves that exceed conventional standards, offering customized solutions for unconventional applications.

Every solution is developed in full compliance with current international regulations, but with the utmost attention to the client’s specific needs. Our goal is to provide reliable, efficient, and perfectly integrable components, even in the most complex applications.

Process Quality

Certified quality in production processes

The system complies with international standards.

Our quality management system is certified UNI EN ISO 9001:2015, ensuring constant control and traceability of every production phase. This approach allows us to offer reliable solutions and respond precisely to customer needs.

Product Quality

Certifications for critical environments and safe applications

Valves designed to withstand the most extreme conditions.

Our valves are PED certified for compliance with pressure equipment regulations and ATEX, ensuring safety even in potentially explosive environments. Every product undergoes rigorous checks to guarantee excellent performance and operational safety in any industrial context.

MTM IN

THE WORLD

MTM IN

THE WORLD

Testing

100% testing for uncompromising quality

Rigorous and customized tests for every need

Every valve produced by MTM Valves undergoes complete testing and quality checks to ensure performance, reliability, and safety.

Our main tests include:

- Functional tests according to international standards such as API 598, API 6D, API 6A, and ISO 5208.

- Fugitive emissions tests (FET) to evaluate potential leaks, following the standard ISO 15848-2 and fire-safe certification according to the standard ISO 10497.

- Cryogenic or low-temperature tests, compliant with the standard BS 6364 and ISO 28921.

We are available to customize tests according to the client’s specific needs.

TEST

ING

Additionally, our non-destructive testing (NDT) performed by trained personnel according to ISO 9712 includes:

- Inspections using penetrant liquids (PT) and magnetic testings (MT).

- Checks of Positive material identification (PMI) and visual testing (VT).

- Tests with ultrasound (UT), radiography (RT), and hardness testing.

- Detailed analyses such as ferrite determination, coating and metal overlay thicknesses.

Thanks to our flexibility, we can evaluate and fulfill any request to meet the most specific needs.

Warehouse

Traceability and speed: our automated warehouse.

More safety, more efficiency, more control.

With our automated warehouses, we ensure efficient and secure management of components, improving every aspect of the supply chain through integration with the company’s management system.

The complete automation of our warehouses allows:

Increased safety for employees by eliminating risks related to manual handling.

Quick response, reducing processing and delivery time.

Full traceability, with detailed tracking of each individual component.

News

Stay updated with the latest news from MTM Valves

Discover what makes MTM Valves a reference point in the industrial valve sector.

5 Criteria for Choosing a Reliable Industrial Valve Manufacturer

Contacts

Contact MTM Valves: personalized consultation and assistance

Our team is at your disposal to meet your company's needs. Request information today.

For more information about our products or to receive assistance, our team is available to offer you qualified support.