Every MTM valve is the result of a precise, structured, and reliable production process. It’s not just about manufacturing components: it’s about ensuring performance, safety, and operational continuity in sectors where reliability is crucial.

1. Order Reception and Technical Analysis

It all starts with the customer’s request. Each project is carefully studied to assess requirements, operating conditions, reference standards, and operational challenges. The goal? To design a valve that precisely meets specific needs, even for unique or non-standard batches.

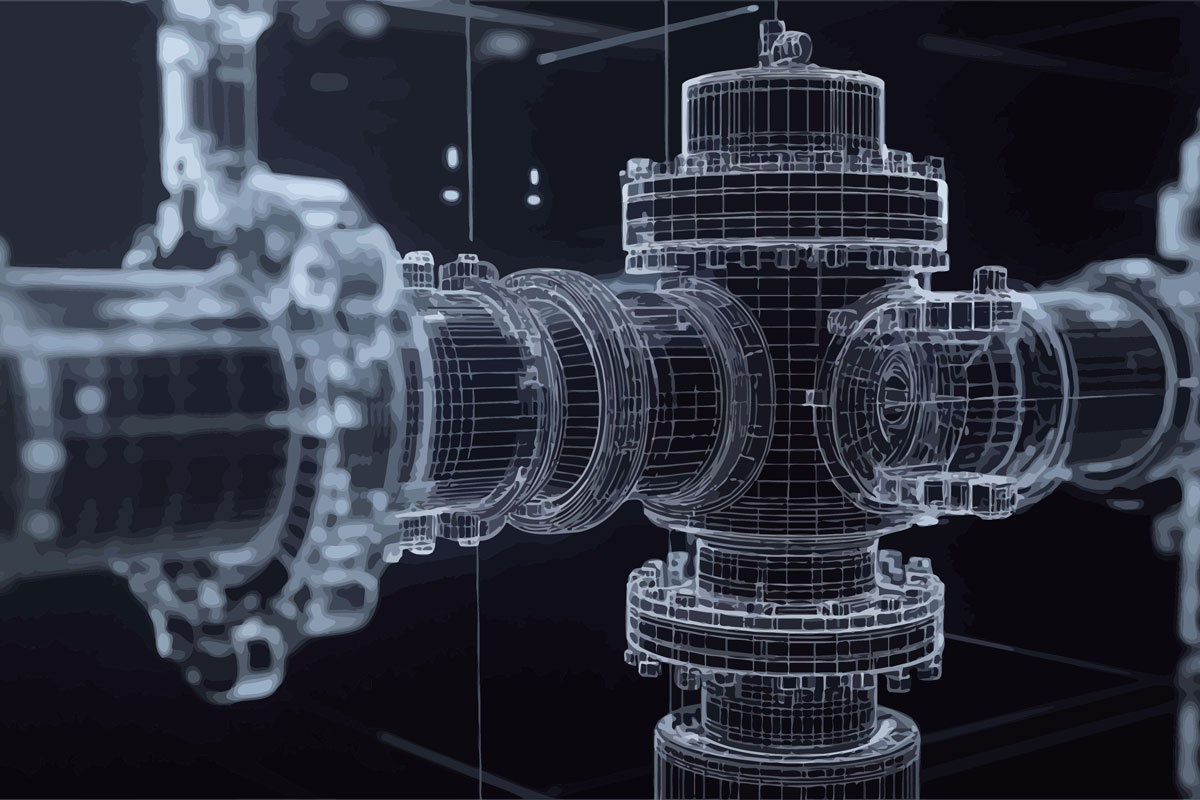

2. Design

Thanks to advanced CAD software, our engineers model the valves in 3D, verifying every detail with fluid dynamic and structural simulations. This allows us to optimize performance, materials, and geometries, reducing development time and ensuring compliance with project specifications.

3. Mechanical Processing and Assembly

Components are manufactured using CNC machines and according to a controlled production flow. Assembly is performed manually by expert technicians to ensure maximum quality control of each part and the absence of errors in critical areas.

4. Standard and Special Testing

Each valve is tested with hydraulic and pneumatic tests up to 600 bar. For extreme applications, MTM Valves conducts cryogenic tests down to -196°C. Special tests are also available upon request, such as NDE, PMI, or functional tests in line with international standards.

5. Packaging and Delivery

Valves are carefully packaged to ensure maximum protection during transport. The automated warehouse and integrated logistics system ensure quick fulfillment times and complete traceability.

The final quality is the result of a consolidated industrial method, evolved over the years and perfected with experience. For this reason, every MTM valve is synonymous with safety, precision, and long-lasting durability.

Contact Us