At MTM Valves, every stage of the production process is designed to ensure the highest quality and reliability of our valves. Thanks to a structured and tested operational model, we combine the most modern design and production technologies with a rigorous testing system, ensuring that every product meets international standards.

Here are the key stages of our production process:

Model

mtm

Production Phases

The operational model of MTM Valves:

excellence in every stage of the production process

From design to shipping, every detail is meticulously handled.

1

Order: from Idea to Design

The process begins with the receipt of the customer’s request. After precisely defining all technical details, our team initiates the design, ensuring full compliance with every specific requirement. Our flexibility allows us to adapt to the needs of customized projects, providing tailored solutions even for the most complex applications.

2

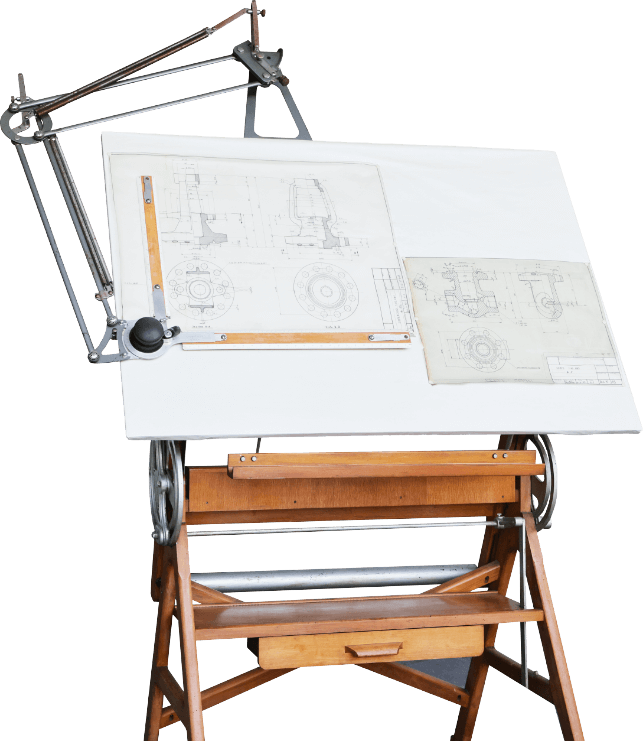

Design: Precision with Impeccable Results

Design is a strategic moment. Through advanced design and simulation software, we develop complete and realistic digital models, simulating behaviors under complex operating conditions. This approach allows us to preemptively assess any potential issues and offer a truly customized design, aligned with the intended use and application sector.

We constantly invest in research and development to design valves that are increasingly efficient, safe, and suited to the evolving needs of our clients and international markets.

3

Production: from Design to Machining

Once the design phase is completed, the project is transferred to our specialized suppliers for the mechanical processing of components. We collaborate with qualified partners who transform the digital design into a physical product, adhering to high standards of precision and quality. Each valve is manufactured to ensure strength, reliability, and durability.

4

Assembly: a Manual Process for Uncompromising Quality

After machining, the valves move to the assembly phase. Here, each component is hand-assembled by expert technicians, ensuring total control over the quality and precision of the assembly. This attention to detail allows us to guarantee that each valve functions perfectly before proceeding to the next stages.

5

Testing: Thorough Tests, Tailored for each Client

Every MTM valve undergoes testing according to international reference standards or specific client specifications. We have equipped stations for pneumatic, hydraulic, cryogenic, and fugitive emission tests, with digital tools for real-time data recording and result traceability.

6

Packaging and Shipping: Protection and Safety

Once testing is passed, the valve is packaged according to its destination and mode of transport. We use materials resistant to moisture, impacts, and mechanical stresses. Each valve is accompanied by the technical documentation, the test certificate, and complete material traceability.