API 6A Class 2000 Psi to 20000 Psi – 1.13/16″ to 11″ and 1/2″ to 10″

API 6A VALVE

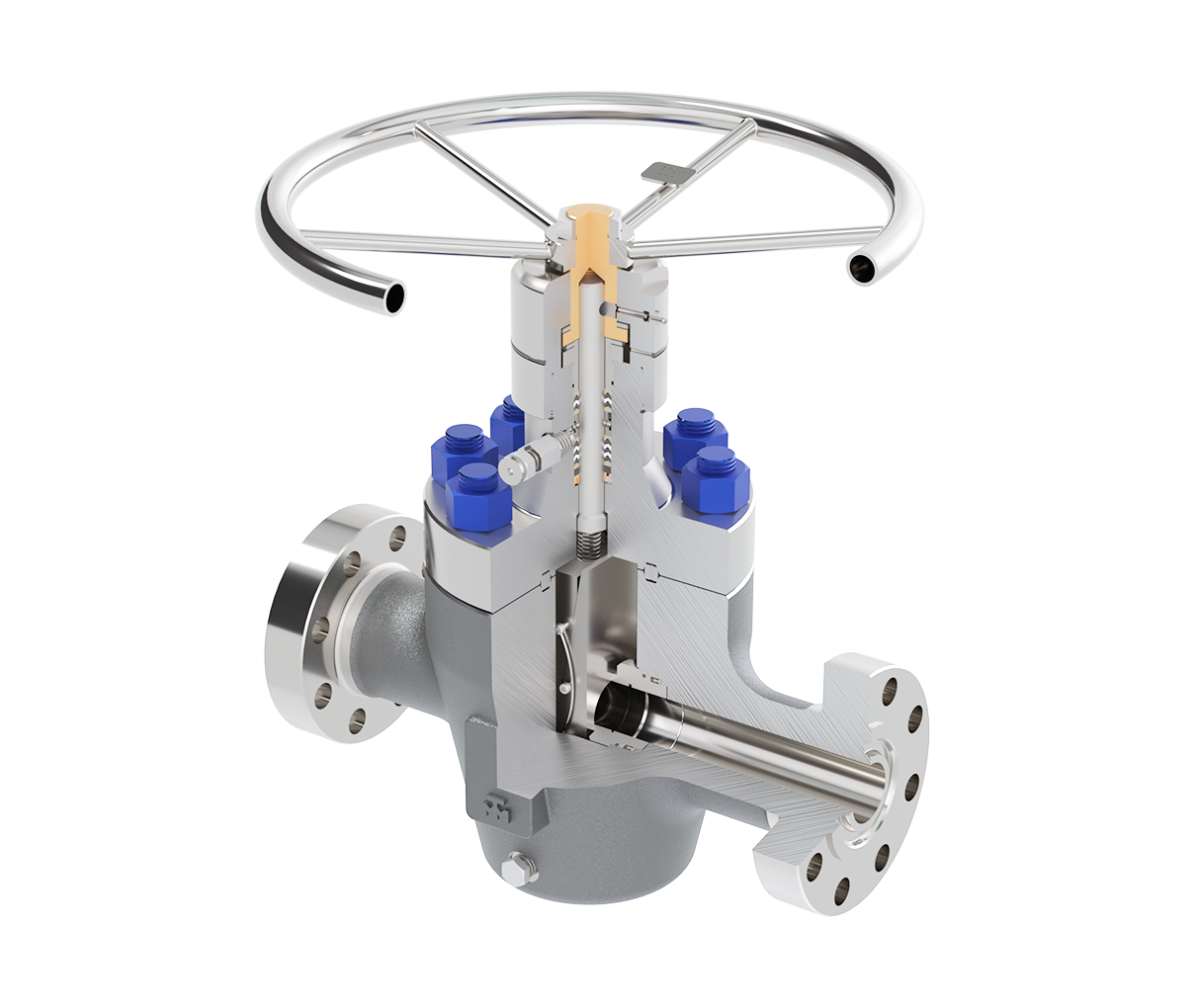

Through Conduit Expanding Gate valve

Richiedi informazioniScarica la scheda tecnica

Classi di pressione e taglie disponibili

Caratteristiche tecniche

- Standard Design: API 6A

- Ends Connection: FLANGED – API 6A, BW – ASME B16.25, HUB – According to Customer Request

- End to End: API 6A, According to Customer Request, Manufacturer Standard

- Body/Bonnet Connection: Bolted Bonnet, Welded Bonnet, Pressure Seal

- Seat Type: Floating

- Obturator Type: Single Expanding Gate, Double Expanding Gate

- Stem Type: Outside Screw & Yoke,Inside Screw & Yoke, Rising Stem, Non Rising Stem, Rotating Stem, Non Rotating Stem, Anti Blow Out

- Back Seat Type: Integral or Renewable

- Body/Bonnet Gasket: Metal – Ring Joint, BX, Lenticular

- Seat Seal: Metal

- Body/Seat Seal: O-ring; Lip Seal; PTFE Chevron Type

- Stem Packing: Graphite, PTFE

- Operator Type: Manual: Handwheel or Gearbox, Manual : Handwheel or Gearbox

- Available Materials: Carbon Steel, Low Temperature Carbon Steel, Martensitic Stainless Steel, Low Alloy Steel, Austenitic Stainless Steel, Duplex, Super Duplex, Nickel Alloy Steel

- Additional Features & Accessories: Locking Device, Position Indicator, Stem Protection, Packing Complete with Lantern, Ring and Grease Injector, Packing Vacuum Service, Loaded Spring Packing, Extended Bonnet, Collar Drip Plate, Insulation, Extended Stem, Quill, Nipples, Gusset, Jacket and Semi Jacket, Bare Stem complete with actuator flange, Operator Antitamper

- Vent & Drain: Plugged, Flanged, With Valve, Any type of connection upon request

- Testing and Certification: Testing: Hydrostatic, High Pressure Gas, Pneumatic and Functional, API 6A – ISO 5208, Cryogenic and Low Temperature Test: BS 6364 – ISO 28921, Fugitive Emission Test: ISO 15848, Fire Safe: ISO 10497 – API 6FA, PED 2014/68/EU Mod. H, ATEX 2014/34/EU

Ad hoc engineering to suit customer projects requirements.